Aluminum is one of the most commonly used metals in the world because of its excellent strength-to-weight ratio, low costs, and recyclability.

- Aluminum

- Brass

- Bronze

- Copper

- Stainless Steel

- Steel

- Titanium

Aluminum is one of the most commonly used metals in the world because of its excellent strength-to-weight ratio, low costs, and recyclability.

An electrochemical process that convers the metal surface into a decorative, durable, corrosion-resistant finish. The purpose of anodizing is to form a layer of aluminum oxide that will protect the aluminum beneath it. Another benefit of anodization is its decorative purpose because it allows different dye colors.

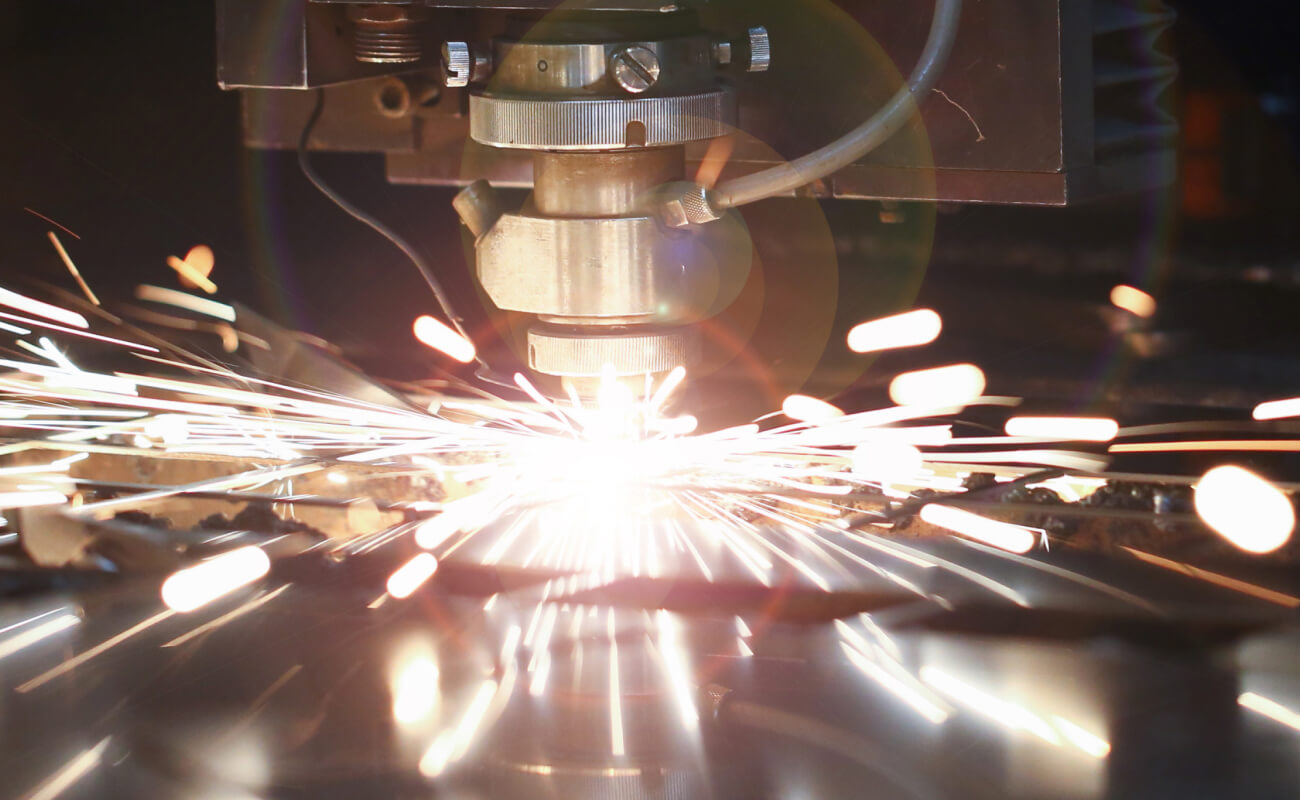

Stands for Computer Numerical Control, an advanced control of machining process to ensure accuracy and precision. We offer wide ranges of CNC machines including milling, lathe, router, welder, grinder, laser, and laser.

Also called pressing, involves placing flat sheet metal, in either coil or blank form, into a stamping press. It’s a manufacturing process used to convert flat metal sheets into specific shapes. Widely used in automotive, aerospace, and other industries.

Sandblasting is a wide-used process to remove imperfections, paint, rust and other contaminants from a surface. It’s an important step in surface coating preparation, as it cleans a substrate and creates a surface that will hold a protective coating.

A widely-used machining process that deforms sheet metal to create metal products. When turning, the workpiece is rotated and a cutting tool is traversed along 1, 2, or 3axes of motion to produce precision diameters and depths.

Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool. It is widely-used process in which a spinning wheel covered in rough particles cuts chips from a workpiece, to produce a smooth finish on flat surface.

A widely-used metal forming process where metal is heated before it is manipulated to the desired shape by hammering, pressing, or rolling. Almost all metals, ferrous and non-ferrous, can be forged.

Stands for Physical Vapor Deposition. A advanced process in which the material goes from a condensed phase to a vapor phase and then back to an extremely thin film condensed phase. It’s used to produce a thin layer of protective and decorative coating that’s harder and more corrosion resistant than regular plating process. It’s also more environmentally friendly.

International standard that specifies requirements for a quality management system (QMS). We use the standard to demonstrate the ability to consistently provide products and services that meet customer and regulatory requirements.

International standard that specifies requirements for an effective environmental management system (EMS). We use this framework to improve our environmental performance through more efficient use of resources and reduction of waste. We’re committed to do our part for our planet.

International standard that support medical device manufacturers in designing quality management systems that establish and maintain the effectiveness of the processes. It ensures the consistent design, development, production, installation, and delivery of medical devices that are safe for their intended purpose.

International Quality Management System (QMS) for the automotive industry. Developed by the International Automotive Task Force (IATF), emphasizes the development of a process oriented QMS that provide continual improvement, defect prevention and reduction of variation and waste in the supply chain.

Tell us how to reach you, and include a message with any other details we should know.

Phone: +1 (408) 321-8869

Address: 1070 Stewart Dr Suite #4, Sunnyvale, CA 94085, USA

Email: hello@artizen.us

A great product starts with a great conversation

Email: hello@artizen.us